Lb Block

If you've ever worked with heavy machinery or structures, you're likely familiar with lb block. These weighty blocks can be essential in creating a stable and secure foundation, but they can also pose a number of challenges. In this blog post, we'll explore the ins and outs of lb block, from its uses to its drawbacks, and help you get a better understanding of this important element in construction and engineering.

Pain Points of LB Block

The main challenge with lb block is, of course, its weight. These blocks can be incredibly cumbersome to move and position, which can make the construction process more time-consuming and difficult. Additionally, their weight can make them a hazard on a construction site, as they may shift or become unbalanced if not handled carefully. Finally, lb block can be expensive, which may make them a less attractive option for smaller projects or those on a tight budget.

The Target of LB Block

The purpose of lb block is to provide a stable and secure foundation for heavy machinery or structures. By placing these blocks strategically, engineers and construction professionals can help distribute weight more evenly across the ground and prevent sinking or shifting. LB block is used in a wide variety of applications, from bridge construction to heavy machinery support to the creation of retaining walls.

Main Points About LB Block and Related Keywords

LB block is a crucial element in many construction and engineering projects. While they can be heavy and expensive, they are often essential in creating a stable and secure foundation. Engineers and construction professionals must take care when working with lb block, to ensure the safety and stability of the site. Some common uses for lb block include bridge construction, retaining wall creation, and machinery support.

My Personal Experience with LB Block

As a construction worker, I've worked with lb block on a number of projects. While they can be incredibly heavy and unwieldy, I've found that they are often the best way to create a secure foundation for larger structures. One of the most challenging projects I've worked on involving lb block was the construction of a large retaining wall. We had to move the blocks carefully and precisely to ensure that the wall was steady and level, but once we were done, it was clear that the lb block had done its job well.

Image Courtesy: Pinterest

The Pros and Cons of LB Block

There are both advantages and disadvantages to using lb block in construction and engineering. On the one hand, lb block can be incredibly effective in creating a stable foundation, especially for larger or heavier structures. They can help distribute weight more evenly across the ground, prevent sinking, and ensure that the structure is level. However, these blocks can also be quite heavy, which can make them difficult or even dangerous to move and position. They can also be expensive, which may make them a less attractive option for some projects.

Image Courtesy: Chegg.com

Types of LB Block

There are a few different types of lb blocks, each with their own unique properties and best uses. Some common types of lb blocks include concrete blocks, steel blocks, and sandstone blocks. Concrete blocks are typically the most affordable option and are often used in the creation of retaining walls or other large structures. Steel blocks, on the other hand, are much stronger and more durable, making them a good choice for machinery support or other heavy-duty applications. Sandstone blocks are often used for decorative purposes, as they can be shaped and carved into a variety of designs.

Image Courtesy: THK Store

How to Work Safely with LB Block

When working with lb block, it's essential to take all necessary safety precautions. This includes wearing appropriate safety gear, such as hard hats and work gloves, and ensuring that the area around the blocks is clear of debris or obstacles. Additionally, it's important to move the blocks slowly and carefully, using equipment like cranes or hoists whenever possible. Finally, be sure to carefully inspect each block before using it, to ensure that it is free of cracks or other damage that could compromise its stability.

Question and Answer Section About LB Block

Q: What are some of the best uses for LB block?

A: LB block is often used in construction and engineering to create a secure foundation for large structures, such as bridges or retaining walls. Additionally, they can be used for heavy machinery support and to distribute weight more evenly across the ground.

Q: How can I move and position LB block safely?

A: When moving and positioning LB block, it's important to take your time and use appropriate equipment, such as cranes or hoists. Additionally, it's essential to wear appropriate safety gear and ensure that the area around the blocks is clear.

Q: What are some of the drawbacks of using LB block?

A: LB block can be heavy and cumbersome to move, which can make construction more time-consuming and difficult. Additionally, they can be expensive, which may make them a less attractive option for smaller projects or those on a tight budget.

Q: What are some different types of LB block?

A: Some common types of LB block include concrete blocks, steel blocks, and sandstone blocks. Each of these has its own unique properties and best uses, depending on the specific project.

Conclusion of LB Block

While LB block may pose some challenges, it is often an essential element of construction and engineering projects. From supporting heavy machinery to creating stable foundations for buildings or bridges, LB block can help ensure the safety and stability of any construction site. By taking appropriate safety precautions and selecting the right type of block for the job, engineers and construction professionals can make the most of this valuable resource and create stable and secure structures that will stand the test of time.

Gallery

Solved: The 200-lb Block Is Sitting On A 30 Degree Incline... | Chegg.com

Photo Credit by: bing.com / block lb degree sitting inclined solved incline friction transcribed problem text been show surface

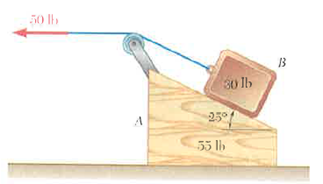

Solved: The 30-lb Block B Is Supported By The 55-lb Block A And

Photo Credit by: bing.com / supported

Solved The 20-lb Block A And The 30-lb Block B Are Supported | Chegg.com

Photo Credit by: bing.com / solved lb block mechanical engineering answers transcribed problem text been show questions

THK Store-HSR-LB Block

Photo Credit by: bing.com / lb hsr block skip beginning

FOR SALE!!! A Stunning 150 Plus Pound Swage Block!! It Measures 19 1/2

Photo Credit by: bing.com / swage blacksmith